Everwin Technical Ceramic Co.,Ltd

The reaction bonded silicon carbide ceramic (SiSiC) for abrasion resistant is extreme wear, thermal shock and high temperature resistance.It is an ideal option of materials for wear applications, such as pipe linings, cyclone lining, flow control throttle valves and larger wear components in mining and other industries.

1.Introduction:

The reaction bonded silicon carbide plate is an ideal wear resistant material. The fine particles of alpha-SiC and additives are pressed into plain billets. It contacts with liquid silicon at high temperature. The carbon in the billets reacts with infiltrated silicon to form beta-SiC. Combining with alpha-SiC, free silicon fills the pore, thus obtaining highly compact ceramic materials. It can be used in medium concentration of acid or alkali medium.

2.Physical characteristics of Duratec reaction bonded silicon carbide plate:

Item | Unit | Data |

Temperature of application | ℃ | 1380℃ |

Density | G/cm3 | >3.02 |

Open porosity | % | <0.1 |

Bending strength | Mpa | 250 (20℃) |

MPa | 280 (1200℃ ) | |

Modulus of elasticity | GPa | 330 (20℃) |

GPa | 300 ( 1200℃ ) | |

Thermal conductivity | W/m.k | 45 (1200℃ ) |

Coefficient of thermal expansion | K-1 ×10-6 | 4.5 |

Rigidity | / | 13 |

Acid-proof alkaline | / | excellent |

3.Key benefits

(1)Excellent wear resistance, impact resistance;

(2)Super corrosion resistance;

(3)Excellent flatness;

(4)Excellent temperature resistance up to 1350℃

(5)Easy installation;

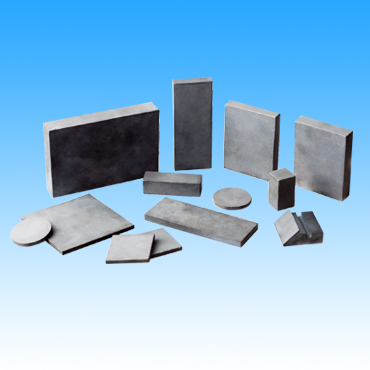

4.Regular Shape and sizes:

(1)SiSiC ceramic tile, with regular sizes 150x100x6/25/50mm, 96x74x8/12/20/25mm, other sizes are available upon requests.

(2)SiSiC ceramic Cone, tube, pipes etc. Other shapes are available upon request.