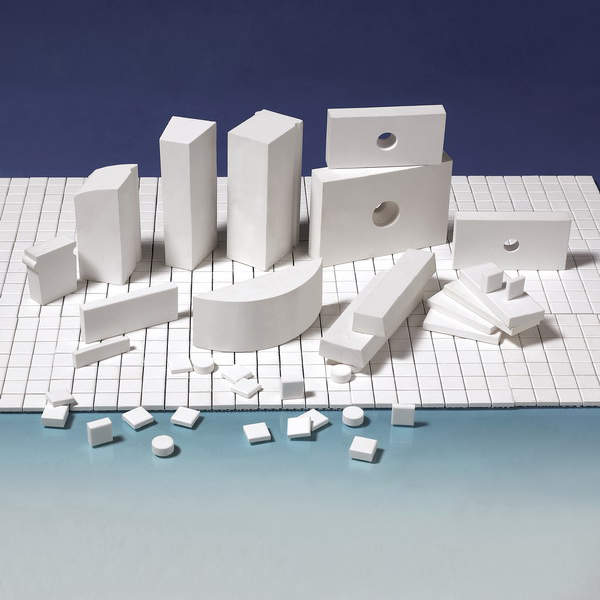

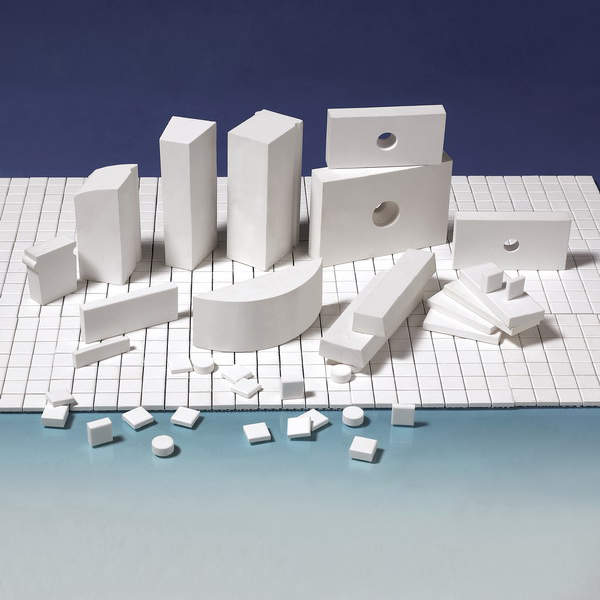

Everwin is supplying various type of high alumina ceramic with excellent wear resistance and impact-resistance.Thanks to the excellent abrasion resistant performance and high impact resistance, the high alumina ceramic will help customer to prolong the service life of the equipment.

1.Introduction:EverWin high alumina ceramic is a kind of material with alumina oxide powder (AL2O3) as the main ingredient, supplemented by other ingredients and sintered at high temperature up to 1700℃ . It is widely used as abrasion resistant material in coal conveying, material conveying, iron & steel works, thermal & power plants, mine, etc. All wear machinery and equipment can choose different types of high alumina ceramic according to different applications.2.Technical Specification:Products | ET85 ® | ET92 ® | ET95 ® | ET97 ® |

Alumina Content (%) | ≥85 | ≥92 | ≥95 | ≥96 |

Viker Hardness (Hv50) | ≥980 | ≥1088 | ≥1150 | ≥1247 |

Rate of Water Absorption(%) | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Fracture Toughness(Mpa 0.5 ) | 5.0 | 5.30 | 5.80 | 6.80 |

Bulk Density (g/cm3) | ≥3.30 | ≥3.63 | ≥3.65 | ≥3.80 |

Grain Size(μm) | 3-25 | 1-6 | 8-20 | 2-15 |